|

|

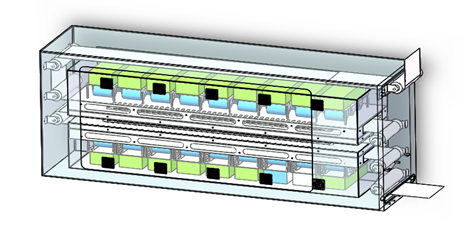

Pulse Light Sterilization Equipment

for Milk juice peptide powder purified water beer wine pharmaceuticl

Liquid Sterilization

1. Currently widely used in the sterilization process of collagen, egg white, and various beverages;

2. Pulse strong light sterilization equipment is undergoing preliminary validation in industries such as beer and fruit drinks.

Advantages:

1. Cold sterilization technology, does not generate heat, does not damage the odor and taste of the liquid;

2. Low energy consumption, 90% lower than specific heat sterilization energy consumption;

3. Low cost, no maintenance required during use£»

4. Easy to install and operate.

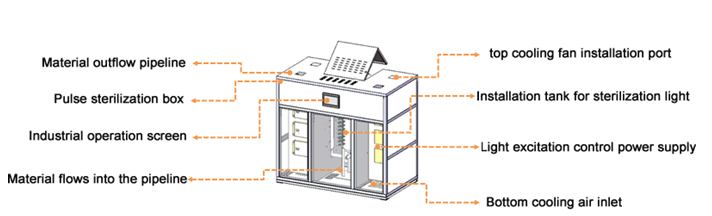

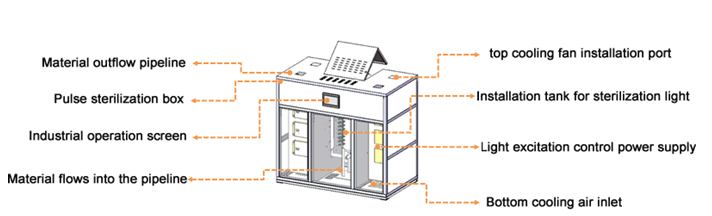

Appearance size: 1800X1000X1800mm ?????Voltage: 220V/50Hz

Equipment weight: ¡Ü 550Kg ????????????????Power: 2KW

Environmental temperature: -10-40 ¡æ????? ?Environmental humidity: ¡Ü 80%

Equipment Advantages:

1. The utilization rate of pulsed strong light tubes has been increased by 35%;

2. Smaller equipment size reduces footprint;

3. Modular design can upgrade sterilization configuration according to production needs.

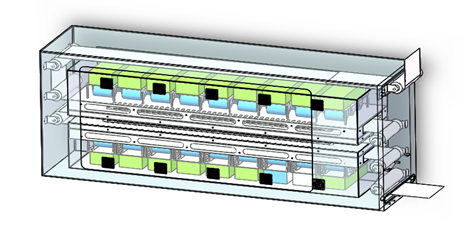

- Surface Sterilization Equipment

Used for surface sterilization of objects, it is currently widely used for sterilization of various packaging materials.

1. Appearance size: 900X300X180mm (single module)

2. Power: 0.55 KW

3. Sterilization speed: 1440 meters per hour (400mm/second)

4. Sterilization effect: 99.999%.

Introduction of Sterilization Technology:?????????????

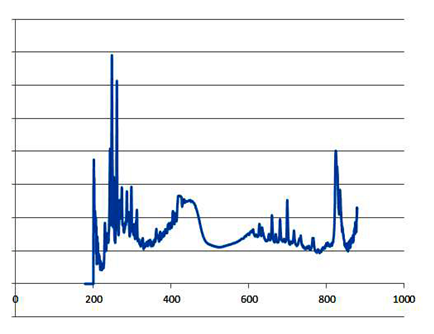

1. Adopting high-energy broadband pulsed xenon light (with a spectral range of 190nm-1200nm), its spectral energy is hundreds of times that of traditional ultraviolet light, instantly producing extremely high-energy visible light, ultraviolet, and multiple electromagnetic wave aggregation effects

2. High sterilization efficiency, capable of achieving a sterilization effect of over 99.999%

3. Low energy consumption, saving 80% -90% energy compared to traditional ultraviolet lamps

4. The module design is flexible and can adapt to different equipment production lines

5. Cold sterilization technology, especially suitable for sterilizing temperature sensitive items

6. Flexible control, start and stop immediately

7. No use of chemical reagents, no pollution or residue

Principles??????? ??????????????????????????????????

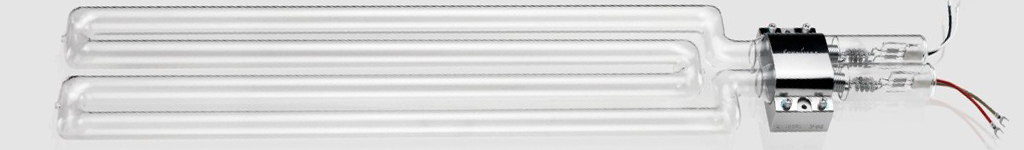

Pulse light sterilization technology is a technique that uses strong white light flashing to sterilize. The generation of pulsed light requires two devices to complete:

??????

(1) A release system for energy storage with power amplification function, which accumulates electrical energy for a relatively long time (a fraction of a second) and then releases it to do work in a short time (a millionth or a thousandth of a second), thus amplifying power. The result is that within the working cycle, only the average energy is consumed to obtain a relatively high peak energy, achieving instant sterilization.

(2) The photoelectric conversion system stores the generated pulse energy in an inert gas lamp and produces high-intensity instantaneous pulse light through ionization. The wavelength of

The killing effect of pulsed strong light on different bacterial species

pulsed light ranges from the ultraviolet region to the near-infrared region, with ultraviolet being the main band responsible for sterilization, while other bands have a certain synergistic effect.

Bacterial species |

Handling method |

Killing effect |

source |

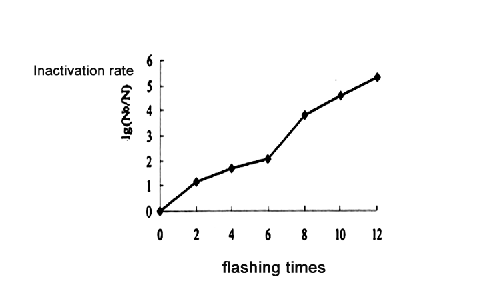

Escherichia coli |

Radiation intensity 0.5J/cm2?

Flashing 6 times |

6 Order of magnitude |

??College of Forestry, Northeast Forestry University

School of Food Science, Shenyang Agricultural University |

Bacillus subtilis |

Input energy 700J

Flashing 6 times |

5 Order of magnitude |

South China University of Technology

College of Food Biotechnology |

Mononuclear cell proliferation

Listeria monocytogenes |

Single input 3J

Flashing 7 times |

4 Order of magnitude |

Strathclyde University, Scotland

College of Biological Sciences and Biotechnology |

Salmonella bacteria |

Single input 3J

Flashing 6 times |

4 Order of magnitude |

Strathclyde University, Scotland

College of Biological Sciences and Biotechnology |

Staphylococcus aureus |

Radiation intensity 5.6J/cm2?

Flashing 5S |

8 Order of magnitude |

Pennsylvania State University, USA

College of Agriculture and Bioengineering |

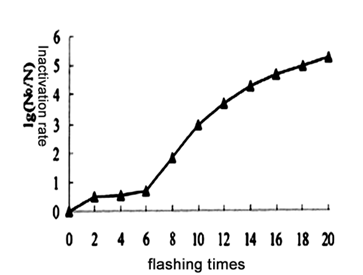

Brewing yeast |

Input energy 300J

Flashing 8 times |

7 Order of magnitude |

South China University of Technology

College of Bioengineering |

Beer yeast |

Single input 7J

Flashing 6 times |

6.8 Order of magnitude |

Ghent University of Food Science in Belgium

Microbiology and Food Chemistry Laboratory |

Aspergillus niger |

Input energy 700J

Flashing 5 times |

4 Order of magnitude |

South China University of Technology

College of Bioengineering |

Herpes virus

HSV-1 |

1.0J/cm2Total dose |

5 Order of magnitude |

Hertfordshire, UK

Institute of Biological Food Research |

Bovine herpesvirus |

2.0J/cm2?Total dose |

4.8 Order of magnitude |

Hertfordshire, UK

Institute of Biological Food Research |

Hepatitis A virus |

2.0J/cm2?Total dose |

5 Order of magnitude |

Hertfordshire, UK

Institute of Biological Food Research |

Pulsed strong light on Escherichia coli and Bacillus subtilis killing effect curve?

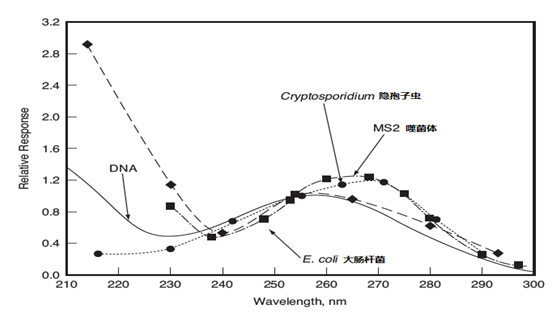

Inactivation curves of different microorganisms at different wavelengths

Equipment advantages?

|